China Manufacturer for Pink Reflective Stickers - Reflective Flame Fabric Tape| 100% FR Treated Cotton | Fluorescent Lime Yellow Color + Silver Color + Fluorescent Lime Yellow Color | Flame Resistant | Home Wash 50 cycles @ 60°C (ISO 6330) | OEKO-TEX 100 | EN ISO 20471 | ANSI-ISEA 107 | NFPA 1971 | Dry-Cleaning 30+ cycles (ISO 3175) | Don’t Industrial Wash – XINLIYUAN

China Manufacturer for Pink Reflective Stickers - Reflective Flame Fabric Tape| 100% FR Treated Cotton | Fluorescent Lime Yellow Color + Silver Color + Fluorescent Lime Yellow Color | Flame Resistant | Home Wash 50 cycles @ 60°C (ISO 6330) | OEKO-TEX 100 | EN ISO 20471 | ANSI-ISEA 107 | NFPA 1971 | Dry-Cleaning 30+ cycles (ISO 3175) | Don’t Industrial Wash – XINLIYUAN Detail:

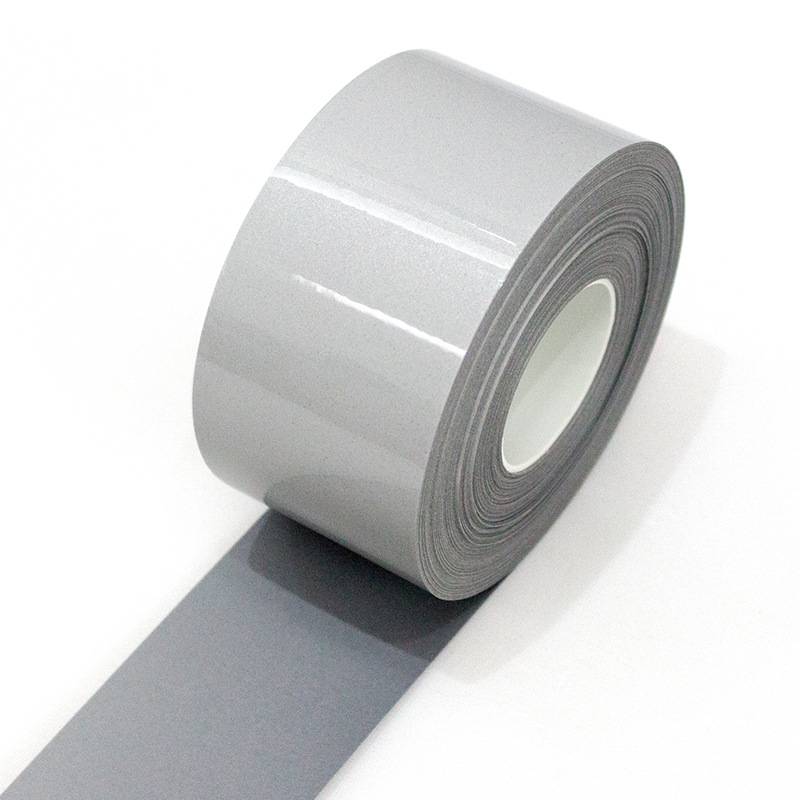

| Product | A4020-FR-FY |

|---|---|

| Material | 100% Cotton, Flame retardant |

| Finish | Flame retardant |

| Colour | Yellow-SIlver |

| Industrial wash | Allowed |

| Box, Volume | 0.0365 CBM |

| Roll, Length | 100 meters |

| Roll, Weight | 2.55 kgs |

| Roll, Width | 50mm |

| Rolls per Box | 10 rolls |

| Box, Weight (Netto) | 25.5 kgs |

| Box, Weight (Brutto) | 26 kgs |

| Meters per Box | 1000 meters |

| Certifications | EN 20471, EN 469, NFPA 2112, OEKO-TEX 100 |

| Wash Performance | Industrial Wash, 100×60°C, 30×92°C, 50×75°C |

| HS code (NCM code) | 5907009000 |

Home Wash (Domestic Laundry) Guidelines

A colored clothing wash program without pre-wash should be used. Follow below recommendation could maintain the duability of retro-reflective to its maxium lifespan.

Recommendation:

- Detergent: Brand powdered household detergents should be used.

- Refer to the detergent manufacturer?s recommendations for dosage in areas of high water hardness and for various degrees of garment soiling.

- Wash temperature range: 15°C to 60°C

- Some items could be extended to be home-washed with a wider range of washing temperature than above.

- Some items could be applicable to wash temperature ranging from 0°C to 90°C for those garment requiring harsher cleaning. Read the physical performance of each reflective tape for the details.

- Max. Wash time at highest wash temperature: 12 minutes

- Max. Program time: 50 minutes

- Use of temperatures lower than 60°C will increase the lifetime of the reflective material.

- Actual lifetime will be dependent upon the detergent system and list dosage level.

- Load factor higher than 65% might lead to enhanced abrasion of the retro-reflective material

Drying Conditions

Tumble Dry: Tumble drying should be performed in a commercially available household dryer

Air Drying: Line drying is recommended where possible.

Hang-Up Drying: on line or rack

Tumble drying and tunnel/air drying are both recommended and applicable to this series of retro-reflective tape. Follow below recommendation will prolong the durability of product.

-

- Using the medium dry setting.

- Exhaust temperature should not exceed 90°C.

- Do not overdry.

Dry Cleaning Conditions

Cleaning process should be based on a pre- and main-bath only.

For P it is recommended to only use pure perchloroethylene.

Adjust load and solvent level to give a moderate mechanical action.

- Max. solvent temperature: 30°C

- Recommended drying temperature: 48°C

Care and Maintenance Instructions

Washing/cleaning conditions harsher than those recommended below could significantly diminish the brilliance of the retro-reflective performance and shorten the product?s lifetime. Therefore, the instructions must be strictly followed.

- No pre-soaking.

- No application of high alkaline products (e.g. heavy duty products or stain removal products).

- No application of solvent detergents or micro-emulsions.

- No additional bleaches.

- Do not over-dry. Reflective material temperature should not exceed 90°C at any time during drying.

- For application on rainwear, a regular fluorocarbon treatment of the garment is recommended.

- Chemical splashes should be removed with a soft, dry cloth. Cleaning the garment the same day is recommended.

- Splashes of strong acids or alkalis should immediately be neutralized with plenty of water.

- Contamination with toxic or poisonous substances or biocontamination will require the application of a specific decontamination process.

- Application of high alkaline products, high pH-products, bleaches etc. is not recommended.

- Do not over-dry. The temperature of the material should not exceed 90°C at any time during drying.

- No chlorine bleach.

- No bleaches on oxygenic basis (e.g. sodium perborate bleaches).

- Do not store a wash batch even in a low concentration of bleach.

Special Cleaning Instructions

|

|

|

Wash: Machine Wash Hot, 60°C |

|

Bleach: Do not bleach |

|

Dry: Tumble Dry Low |

|

Dry-clean: Dry clean, PCE (Petroleum Solvent) only |

Product Application Guideline

We recommend that all customers, in accordance with good manufacturing practices, establish an ongoing quality system which includes maintaining lot/roll identification throughout the garment production process.

Customer should also store input materials and final products in accordance with manufacturer recommendations, as well as implement continuous testing throughout their production and on their finished garments that reflects their garment needs.

Cutting

Die-cutting is recommended, although it can also be hand-cut or guillotined.

Note: Use very sharp cutting knives only and cut from the reflective side.

Sewing

For the best results, sew in place using a lockstitch and with no more than 12 stitches per inch (2.54 cm), and not less than 5/64? (2 mm) from the edge of the reflective fabric. Recommend for applying to light and medium weight fabrics.

Printing

Prior to printing, wiping the surface with a soft cloth lightly dampened with isopropyl alcohol may help ink adhesion

Printed areas will not be retro-reflective.

- Screen Printing – Images may be printed on the surface of AT SAFETY Reflective Material – Reflective Fabric. All inks should be continuously tested to ensure acceptable adhesion in the event of change occurring in the manufacturing process or composition of the ink. Prior to printing, wiping the surface with a soft cloth lightly dampened with isopropyl alcohol may help ink adhesion. Printed areas will not be retro-reflective.

- Sublimation Printing – This printing method is applicable to AT SAFETY Reflective Material – Reflective Fabric.

IMPORTANT

Images may be printed on the surface of reflective material ? fabrics. All inks should be continuously tested to ensure acceptable adhesion in the event of changes occurring in the manufacturing process or composition of the ink.

Test each application according to appropriate care instructions required for the finished product.

Actual life of AT SAFETY Reflective Material – Retro-Reflective Fabric/Tape depends on cleaning methods and wear conditions.

Handling Precautions

AT SAFETY Reflective Material – Retro-Reflective Fabric/Tape contains an aluminum layer as part of their construction. Blemishing of this aluminum layer can occur if surface of the product has direct contact from hands during application and is then exposed to hot and humid conditions, greater than 26.7 °C (80 °F) and greater than 70% relative humidity, for a period of weeks. These blemishes do not affect performance of the product. But potential blemishes should be carefully considered as an important risk in marketing of end-use products.

AT SAFETY Reflective Material – Retro-Reflective Fabric/Tape contains an sand-feeling reflective layer which is bonded to a textile fabric via an eco-friendly adhesive. Chemical moisture, liquid, oil, or other chemical elements may lead to a series of chemical reactions for a certain period of time, then result in a series unexpected subsequence on the reflective layer of fabric. Any remains of chemical elements happen to direct contacting to surface of fabric should be cleaned immediately.

We recommend that all customers, in accordance with good manufacturing practices, establish an ongoing quality system which includes maintaining lot/roll identification throughout the garment production process.

Customer should also store input materials and final products in accordance with manufacturer recommendations, as well as implement continuous testing throughout their production and on their finished garments that reflects their garment needs.

For lamination operations, customers should periodically check their equipment to ensure that the temperature set point matches the platen or roll temperature and that the temperature is uniform across the lamination area.

Specific Safety Information

Various environmental factors, like line of sight, rain, fog, smoke, dust and visual noise can influence retro-reflectivity.

- The reflective intentsity of retro-reflective tape can also be diminished in extreme weather conditions.

- Fog, mist, smoke and dust can scatter the light from headlights, the wearer must be aware that detection distance will be severely reduced.

- Visual noise (contrast variations in the visual field) decreases the contrast of the reflective material with the background and affects the visibility in low-light conditions.

AT SAFETY Reflective Material – Industrial Wash Reflective Fabric/Tape exceeds the retro-reflective performance requirements in rainfall conditions as defined in EN ISO 20471 and ANSI-ISAE 107.

Initial brightness levels return as the material dries.

Maintenance Misuse

No harsh mechanical treatment, e.g. abrasion with wire brushes or sand paper.

No uniform coating or spraying of oils, protective waxes, inks or paint.

No application of products such as leather spray or shoe shine.

Product Storage

Store in a cool, dry area and use within 1 year of receipt.

Rolls should be stored in their original cartons, whilst partially used rolls should be returned to their carton or suspended horizontally from the core via a rod or pipe.

Cut sheets should be stored flat.

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for China Manufacturer for Pink Reflective Stickers - Reflective Flame Fabric Tape| 100% FR Treated Cotton | Fluorescent Lime Yellow Color + Silver Color + Fluorescent Lime Yellow Color | Flame Resistant | Home Wash 50 cycles @ 60°C (ISO 6330) | OEKO-TEX 100 | EN ISO 20471 | ANSI-ISEA 107 | NFPA 1971 | Dry-Cleaning 30+ cycles (ISO 3175) | Don’t Industrial Wash – XINLIYUAN , The product will supply to all over the world, such as: Montreal, French, Guatemala, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.